3D Bin Picking

BASIC PRINCIPLE

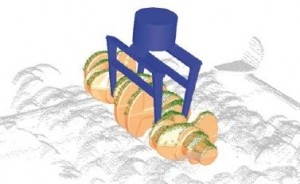

Combine the CAD file of the part with a set of 3D measurements taken on the work scene including the parts to be picked and the environment (container or other). Comparing the digitized virtual point cloud with the part’s CAD model allows to locate the parts in the work scene, and the patented eyesberg3D software ensures that the parts are picked by a collision-free system. The robot receives in real time the position of the part to pick and completely empties the container piece by piece

INDUSTRIAL NEEDS:

- Automate part picking tasks even for complex parts in random arrangement

- Avoid additional packaging costs

- Guarantee a steady and constant cycle (4 to 12 seconds per part picked depending on the size of the robot, the general configuration and scanning or not in hidden time …)

- Guarantee a precise and repeatable positioning of the parts picked (about 0.1 mm to 0.5 mm according to the size of the part)

- Guarantee the non- collision of the clamp with the environment during picking

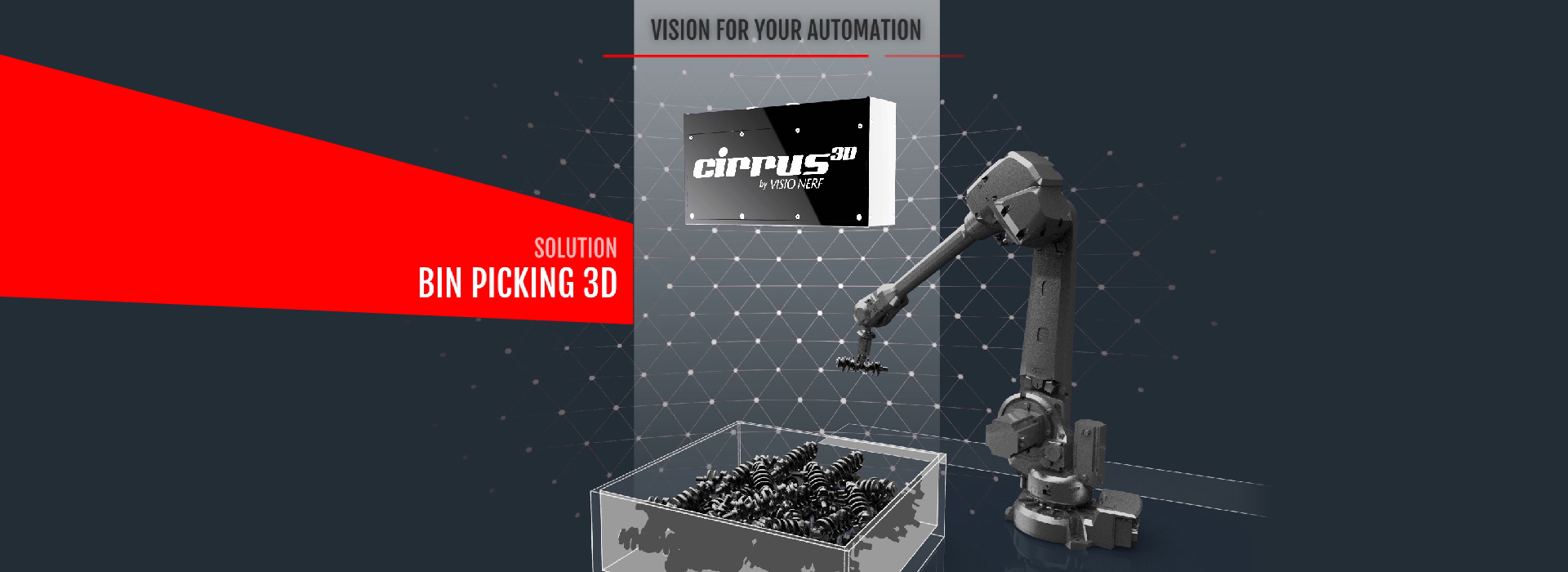

3D VISION

The choice of the 3D sensor is crucial for the global architecture of the Bin-Picking cell: no matter how good the processing software is, a 3D sensor providing a bad point cloud will affect its performance. Several 3D sensor models exist for the acquisition of a point cloud. Each of these sensors is based on different physical principles which depend on the use case to be considered.

DIFFERENT IMPLEMENTATIONS

Cell with fixed optical sensor: traditional Bin-Picking cell

This is the most common situation. The fixed optical sensor, mounted on a frame, scans one or even two bins placed under it.

This layout:

- provides a global view of the scene (and therefore detects a greater number of parts that can be picked).

- does not obstruct the robot work area.

- significantly reduces cycle time in cases like the one shown below.

Situation with a short cycle time:

In this example, the robot is equipped with a double gripper. With a single scan, it grasps two parts widely spaced in the box. During the drop-off phase, the sensor launches a new scan (performed in hidden time). This results in a significant reduction of the cycle time.

Cell with on-board optical sensor

In this case, the sensor is mounted on the robot arm.

Several reasons can justify this implementation:

- The cost: it allows the use of a smaller (less expensive) sensor and only one sensor is required to empty several bins.

- The accuracy: on-board sensors are generally low scan volume sensors but, as they are closer to the workpiece, they have the advantage of providing a point cloud of higher resolution.

- The nature of the parts to be picked: this solution is interesting for relatively long pieces, such as bodywork panels, where only a moving sensor can provide a complete point cloud of the part. However, it is important to be aware of the real risk of collision of the sensor when it is mounted on the arm. The choice of an on-board sensor should not be hasty but genuinely justified.

INDUSTRIAL NEEDS:

- Automate part picking tasks even for complex parts in random arrangement

- Avoid additional packaging costs

- Guarantee a steady and constant cycle (4 to 12 seconds per part picked depending on the size of the robot, the general configuration and scanning or not in hidden time …)

- Guarantee a precise and repeatable positioning of the parts picked (about 0.1 mm to 0.5 mm according to the size of the part)

- Guarantee the non- collision of the clamp with the environment during picking

Complete Process

01

Digitization

The cirrus3D digitizes the actual work scene as a 3D point cloud.

02

Location

The eyesberg3D software locates the best part to pick from these 3D measurements compared to the CAD model of the part. In order to guarantee the picking, the possible areas of overlap by the other parts are simulated by building a virtual work scene. The software also manages the calculation of the robot trajectory to avoid any collision with the work environment.

03

Part Picking

The robot receives the position (3 components in translation) and the orientation (3 components in rotation) of the part to be picked, as well as a “possible” picking choice among the different picking strategies that the technology Eyesberg® allows you to teach to the robot beforehand. Then the robot is programmed to choose among them according to its own constraints (accessibility, singularities …) and to pick the most accessible part

04

Robot Path Planning

the sensor is managing the robot path planning inside the bin for bin picking. The robot program development and integration is easier, and the cost reduced. Moreover, a free collision trajectory is sent to the robot ( avoiding the bin and the environment) which allows the robot to enter in the bin. A simplified integration, shorter associated to a highest productivity: a quick ROI