Robotic Industrial 3D vision sensor

3D vision solutions

The new VISIO NERF 3D sensor, a vision system camera, is perfect to integrate automation into your industrial process in a very simple way. Our Cirrus 3D is an autonomous smart camera, easy to use with the plug and play technology, that can fit in your installation or cell without any specific development.

Used as a fixed or mobile (embedded on the robot) component, with or without eyesberg3D (image processing software), the Cirrus 3D allows the implementation of vision/robotic applications with efficiency and very high quality in your warehouse management system or your production process.

3D VISION SENSORS

Easy integration

Dedicated to industrial use, these sensors are not very sensitive to the environment, dust and variations of brightness in order to guarantee a prime reliability and robustness of your installations (IP 65). Assembly, inspection, identification, location of a single or bulk parts are industrial applications in which the cirrus3D range will bring you an excellent return on investment

Robust

For more than 15 years, VISIO NERF has completed numerous 3D vision projects for quality control or robotic guidance applications. With this great experience, VISIO NERF introduces its range of 3D vision systems called cirrus3D. The cirrus3D is a complete 3D vision system integrated in a single, ready-to-use package, including the eyesberg3D software

High Precision

Your project will be more efficient and better performing with 3D vision versus 2D vision. 2D vision has its limits, especially when it comes to the shape of a part, while 3D vision can recognize, with high precision, a part, whether it is moving, static or rotating on a conveyor. If you want to know more about this 2D to 3D technology (lien vers le guide 2D to 3D). For the location of a part in a bin for example, 3D vision will always be more efficient than 2D vision.

Solutions

Software suite

VISIO NERF has developed easy-to-use and high efficiency implementation tools for the location of parts and quality control during production

Sensors

With our different acquisition technologies, we offer robust solutions that take into account your needs but also the constraints related to the environment of your process such as variations in shades or color of the parts and / or variations in brightness inside the factory, as well as variations in the size and shape of the raw parts.

High Dynamics

Our vision sensors are built to withstand manufacturing environment conditions with ambient dust as well as fluid projections from surrounding machines.

SOFTWARE SUITE

VISIO NERF has developed easy-to-use and high efficiency implementation tools for the location of parts and quality control during production. Its plug-and-play solution can also be used for any automated bin picking process or robot guidance to complete an inspection task.

The new VISIO NERF 3D sensor, a vision system camera, is perfect to integrate automation into your industrial process in a very simple way. Our Cirrus 3D is an autonomous smart camera, easy to use with the plug and play technology, that can fit in your installation or cell without any specific development.

Used as a fixed or mobile (embedded on the robot) component, with or without eyesberg3D (image processing software), the Cirrus 3D allows the implementation of vision/robotic applications with efficiency and very high quality in your warehouse management system or your production process.

SENSORS

VISIO NERF has developed easy-to-use and high efficiency implementation tools for the location of parts and quality control during production. Its plug-and-play solution can also be used for any automated bin picking process or robot guidance to complete an inspection task.

With our different acquisition technologies, we offer robust solutions that take into account your needs but also the constraints related to the environment of your process such as variations in shades or color of the parts and / or variations in brightness inside the factory, as well as variations in the size and shape of the raw parts. The vision system is not affected by any shiny environment.

HIGH DYNAMICS

VISIO NERF has developed easy-to-use and high efficiency implementation tools for the location of parts and quality control during production. Its plug-and-play solution can also be used for any automated bin picking process or robot guidance to complete an inspection task.

Our vision sensors are built to withstand manufacturing environment conditions with ambient dust as well as fluid projections from surrounding machines. As an example, we developed projects for several foundries (lien vers customer cases Renault ou autre plus recent) in the automotive industry.

APPLICATIONS

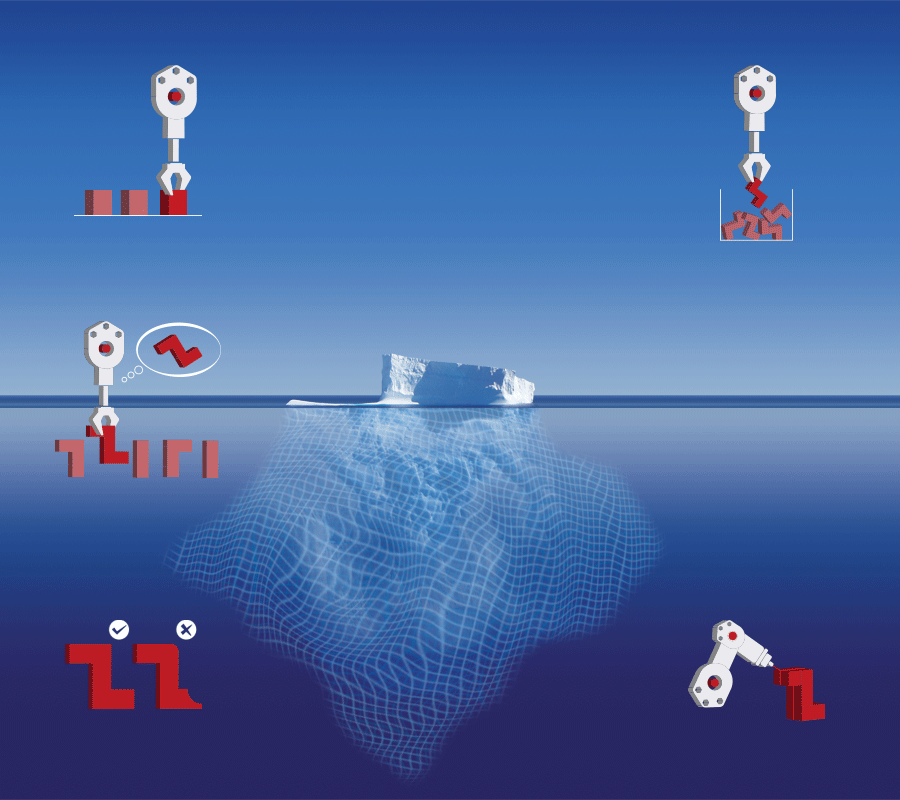

The Cirrus3D sensor is able to locate a part, even it is shiny or matte, get a 3D digital version of the cloud of points and send the coordinates to the robot to pick up the part.

Available on both a fixed location or embedded on the robot, the 3D vision camera helps to guide the robot in its environment to complete its tasks with high precision.

Paired with a CAD file representing the part, our Cirrus 3D sensor gets the 3D cloud of points of the working bin. The picking process is then set up for the robot to pick up the part from the bin without any collision.

By comparing the CAD file of the part and what the smart vision gets, our vision system camera is able to identify a part and make the robot complete a task or apply a treatment to this part.

Used for control in a manufacturing process, the Cirrus 3D can check if the part inspected matches the CAD file and tell the information to the robot.

MORE INFORMATION

VISIO NERF’s teams are available in all parts of the world to support your vision, and your needs in the 3D vision field for the automation of your industrial process