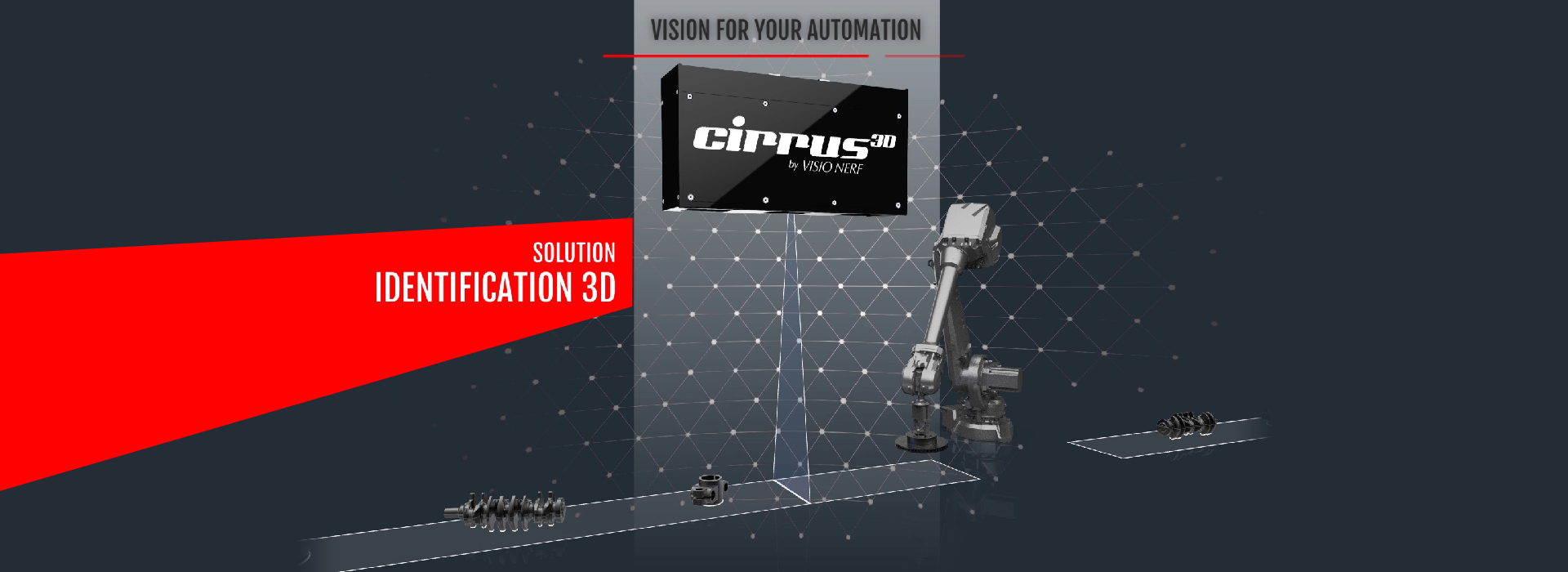

3D Robotic Identification

BASIC PRINCIPLE

3D identification allows, in a heterogeneous flow, to identify one of a few hundred referenced items stored in the Eyesberg® database consisting of 3D surface CAD modeling. By combining the modeling file of the part to be identified with the point cloud generated by a scan of this part, Eyesberg® 3D Identification makes it possible to identify the production part , online, at the time of its manufacturing. This solution makes it possible to then apply a treatment dedicated to each part (robotic paint line, sorting, marking …)

INDUSTRIAL NEEDS :

- Avoid the traditional decision trees inevitably limited in reference quantities to be processed

- Guarantee the production cycle despite the presence of in line sorting issues

- Allow to add a new part reference during production without compromising the solution

- Easy addition or removal of a New reference

- ID in Real-Time …

The Complete Process

The implementation of the Eyesberg® 3D Identification solution requires the preliminary creation of a database of the surface modeling files for the parts to be identified.

Typical example of a response to a need for identification: identification of parts on a robotic paint line. : Eyesberg® 3D Identification allows the paint robot to select the appropriate paint program based on the reference of the part it has received from Eyesberg® 3D Identification

01

Digitization

The cirrus3D scans from the work area to create a 3D point cloud.

02

Part location

The point cloud is analyzed by the eyesberg3D software to identify the part. The parts characteristics are then tested using the software to find the relationship between the acquired point cloud and the CAD model of a known part.

03

Part identification

Sending the identified part information to the operating system of the production line (Programmable automation, robot …).

Typical example of a response to a need for identification: identification of parts on a robotic paint line. : Eyesberg® 3D Identification allows the paint robot to select the appropriate paint program based on the reference of the part it receives from Eyesberg® 3D Identification …